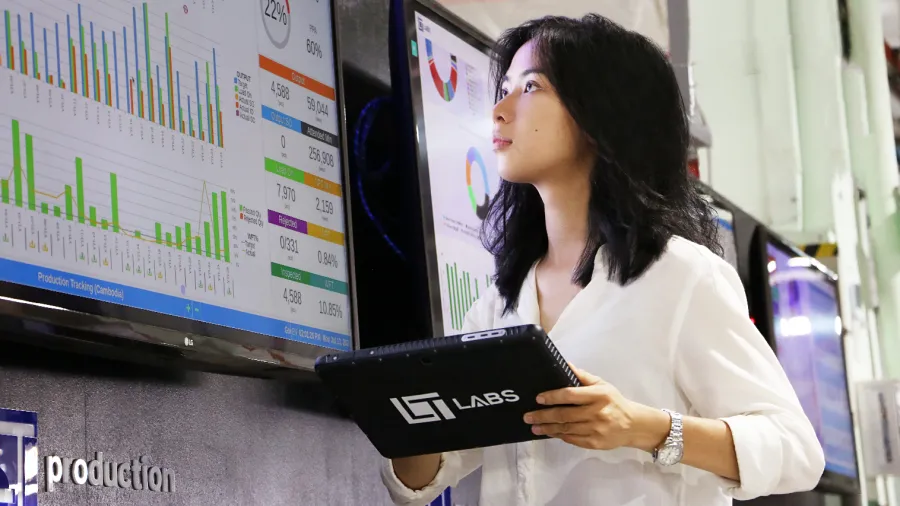

LTLabs’ Connect Suite MES Solutions, shifting from legacy production systems to digitalization

It was awarded with the Software - Apparel trophy at HKB Technology Excellence Awards.

Today's clothing manufacturers need solutions that drive greater operational and production efficiency throughout their entire businesses across myriad functions and locations.

As early as 2019, LTLabs came up with LT Connect Suite solutions in response to the call for digital transformation in the apparel industry. LTLabs saw the immense opportunity to develop a system that will help optimize the production and manufacturing process. With LT Connect Suite, LTLabs has made this possible through the integration of over 30 years of first-hand manufacturing experience and software development expertise.

TEAMconnect solutions have allowed an overflow of opportunities in the apparel industry. Factories and manufacturers can now utilize existing technology to support production workflow harmoniously, increasing productivity while reducing operation cost. This enables factories to easily tackle the intimidating process of digital transformation by beginning with teams.

TEAMconnect was born within a two-year effort to replace manual production work, which is time-consuming, expensive, and inefficient, with a more innovative and digitized one. The new and improved solution plays a part in the end-to-end manufacturing systems (MES), which focuses on a factory’s production line. Eventually, the systems have become more coherent, enabling factories to acquire and analyze valuable data to provide top-notch management across the production floor, promoting real-time visibility and transparency.

There are three main cloud-based applications under TEAMconnect: LTquality, LTmechanic, and LTie. All three systems work jointly in facilitating end-to-end workflow and consolidating shared data. With the accuracy of digitally capturing the data through the platforms, factories can discover hidden costs and eliminate them, resulting in increased collaboration and enhanced overall efficiency.

For the creation of TEAMconnect as the answer to one of the biggest problems in the apparel manufacturing world, there is no question that LTLabs deserves the Software – Apparel award at the Hong Kong Business Technology Excellence Awards. Ultimately, LTLabs envisions their company to lead modernization in the apparel manufacturing industry and maximize production efficiency.

Managing and integrating all systems within the factory ultimately helps create centralization, increasing business visibility.

In just four months within the launch of LTLabs’ TEAMconnect solutions, significant changes in production were seen. There was a 51% reduction in sewing defects, 85% reduction in Non-Productive Time (NPT) caused by sewing, and savings of 13 hours of Non-Productive Time (NPT) per sewing line.

These achievements exhibit LTLabs’ competence and dedication in transforming the apparel sector to build a culture where efficiency in manufacturing and production is held with great value.

Advertise

Advertise